Development of a Tubeball Coal Mill .

The mathematical model of the TubeBall mill was developed based on fluid mechanics; principles electrical engineering, thermodynamics and aerodynamics

WhatsApp)

WhatsApp)

The mathematical model of the TubeBall mill was developed based on fluid mechanics; principles electrical engineering, thermodynamics and aerodynamics

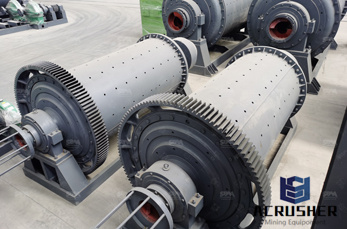

ball mill mechanics China Mining Equipment CO,Ltd. development of a tube ball coal mill mathematical model using the tube ball mill used by edf is a motor driven ...

Artificial Neural Network Modeling of Ball Mill ... and reliable tool to develop a mathematical model to predict the process ... network Model of Ball mill.

Development of a Tubeball Coal Mill Mathematical Model Using Particle Swarm Optimization ()

Research of Mathematical Model of the Ball Mill with Double Inlets and Outlets YUAN Gang PAN Weijia LI Suzhen HAN Qin (College of Energy and Power Engineering ...

Abstract. In this paper, new mathematical models and grinding methods of ballend milling cutter were proposed based on the orthogonal spiral cutting edge curve.

COMPARING POWER AND PERFORMANCE TRENDS FROM ... for a ball mill at between 1 and 10 mm has minimal effect on flow ... JKMRC SAG mill model.

Semantic Scholar extracted view of "A mathematical model for simulating and manufacturing ball end mill" by Hien Nguyen et al.

Title: Development of a Tube Ball mill mathematical model for mill condition and safety monitoring Author: Zachariades, Paschalis

2008 International Conference on Intelligent Computation ... Research of Mathematical Model of the Ball Mill ... Conference on Intelligent Computation Technology ...

Mathematical model of ball wear in grinding mills I. Zeroorder wear rate on ResearchGate, the professional network for scientists.

Read "Modeling and simulation of ball mill coalpulverizing system" on DeepDyve, the largest online rental service for scholarly research with thousands of academic ...

A 55cm ball mill is simulated for ... The discrete element method for the simulation of ball mills. Applied Mathematical ... The discrete element method for the ...

mathematical model ball mill. CHAPTER 14. MODEL ZONING REGULATIONS. ... Mathematical recreations comprise puzzles and games that vary from naive .

The performance of ball end mill cutters in cutting operations is influenced by the configuration of the rake and clearance faces in the ball component.

From the operation mechanism of the ball mill with double inlets and outlets, this paper gives a research work to the simulation of the ball mill with double inlets ...

Using a population balance approach, a general mathematical model is developed for the ball wear in rotary grinding mills. The firstorder partial differential ...

Mathematical modelling the twocompartment mill and classification PhD Thesis, ... as being used in Whiten''s perfect mixing ball mill model, ... Mathematical models

Mathematical model of ball wear in grinding mills. I: Zeroorder wear rate Auteur(s) / Author(s) ... Ball mill; Grinding medium; Wear; Mathematical model;

Contributions to the modelling of the milling process in a planetary ball mill 23 ing impact energy in their study, and they focus on inspecting the collision between ...

Transient solutions to the population balance model of ball wear are given for various wear kinetics. At steady state, a single equation suffices to describe the ball ...

Powder Technology Application IV: A Mathematical Model for Predicting the Internal Parameters of Ball Mill

Mathematical model of a ball mill V. R. Kovalyukh, M. B. Gud . show all 2 hide . Get Price Online. A mathematical model for simulating and manufacturing ball .

Calculation of the power draw of dry multicompartment ball mills 225 The mill load that is the volume of charge in the mill is the principal determinant of

WhatsApp)

WhatsApp)