Abrasive,Cut Off Wheels,Grinding Wheel Manufacturer

These products are used for grinding and polishing of various materials including metals, plastics, and stones. English Español Français ...

WhatsApp)

WhatsApp)

These products are used for grinding and polishing of various materials including metals, plastics, and stones. English Español Français ...

Video embedded· How is cement manufactured? Learn cement manufacturing process thoroughly.

I. Best Practices for Raw Ground Products A. Introduction B. The Grinding Process ... track back to the actual raw materials used in the process.

PRECISION GRINDING PROCESS DEVELOPMENT FOR BRITTLE MATERIALS* Mark A. Piscotty, Pete J. Davis, Kenneth L. Blaedel Lawrence Livermore National Laboratory

materials can be shipped without additional liquid weight. It also can reduce production costs and ... classifiers or screeners to form a closed grinding process loop

Materials and Manufacturing Processes ... it becomes imperative that the grinding process with its parameters must be understood properly ...

New grinding process developments by Tyrolit, ... Grinding Roughs Out a New Niche ... nickelbased alloy materials is common in aircraft engines and components.

Grinding (abrasive cutting) ... These materials lend themselves to grinding because they can be ... The use of fluids in a grinding process is often necessary to ...

Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte ...

Basics of Grinding Fundamental Manufacturing Processes Video Series Study Guide ... The grain size of abrasive materials is important to the process. Large, coarse

New grinding process developments by Tyrolit, ... Grinding Roughs Out a New Niche ... nickelbased alloy materials is common in aircraft engines and components.

As a material removal process, machining is inherently not the most economical choice for a primary manufacturing process. Material, which has been paid ...

Cryogenic grinding permits heatsensitive, thermoplastic, and elastic materials to be economically ground to very small particle sizes. The cryogenic process actually ...

Corundum and silicon carbide belong to the conventional grinding materials, ... Grinding Process, Fig. 13. Grinding wheel wear during grinding with various cooling ...

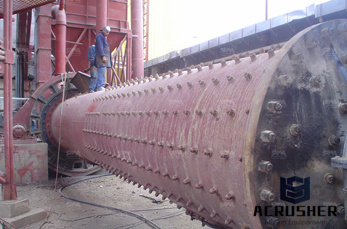

The present chapter will be devoted to a study of the process of grinding within a real mill. ... Grinding Process. ... for grinding materials of various densities, ...

Purdue University''s Materials Engineering''s academic programs have been developed around all major classes of artificial materials, ceramics, metals, glasses ...

Duval Precision Grinding offers precision grinding capabilities across a wide range of common and unusual industrial materials.

Post grinding is the grinding of a mixture of different raw materials in a batch process. Pre grinding means that every raw material is ground separately and ...

raw materials to gold mining is manufactured from Shanghai Xuanshi,It is the main ... mining minerals such as grinding materials processing ... process . Home ...

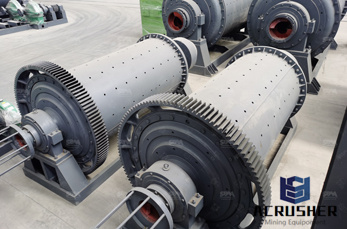

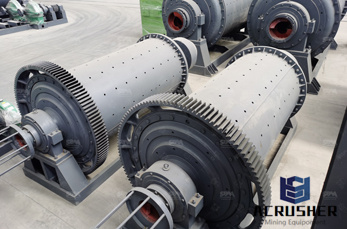

Grinding is an abrasive machining process that uses a grinding wheel as the ... and until recent decades it was the only practical way to machine such materials as

The grinding process requires rapid removal of materials, making Silicon Carbide an obvious choice. It is typically used on ferrous and nonferrous metals.

Electrochemical Grinding Process Overview. ... then ELECTROCHEMICAL GRINDING (ECG) is the best option. Materials that are difficult to machine by conventional methods

Today''s difficulttoprocess workpiece materials and complex, highvalue parts have sparked resurgence in the use of continuousdress creepfeed grinding. At the ...

This article describes which sample materials cryogenic grinding is ... the grinding process should not take more than 3 minutes to prevent the sample from ...

WhatsApp)

WhatsApp)